Dyneema® fiber, also known as Dyneema/Dalima fiber, is technically classified as ultra-high molecular weight polyethylene fiber (UHMWPE), which is the highest-strength material that humans can currently synthesize. Dyneema® fiber is one-thousandth of an inch thick and has a remarkable strength-to-weight ratio, which also makes it the strongest fiber in the world today.

Dyneema® fibers have ultra-long molecular chains, which allow for more efficient load transfer to the polymer backbone. This physical property allows Dyneema® fiber to have higher tensile strength at the same mass and lighter mass at the same tensile strength compared with other fibers.

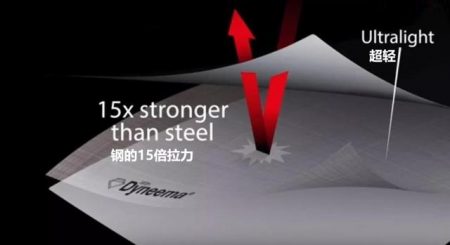

Under the same mass, the tensile force of Dyneema® fiber is 15 times that of steel.

Under the same quality, the tensile force is 40% higher than that of aramid fiber.

It can float on the water surface and can effectively resist the erosion of moisture, ultraviolet light and chemical reagents.

Dyneema® fiber itself is a black technology! Dyneema® fiber products are used in life protection (body armor/cut-resistant gloves), heavy lifting (cables/slings), armor protection, outdoor equipment and other fields.

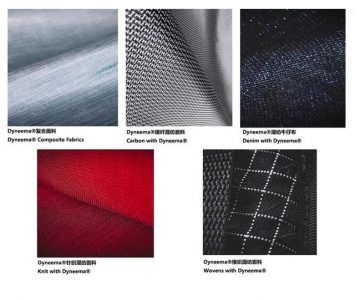

Dyneema® fabric classification

Dyneema® fabrics (Dyneema® Fabrics) refer to fabrics made of Dyneema® fibers through compounding and blending. There are five main types of Dyneema® fabrics currently on the market:

Among them, Dyneema® carbon fiber blended fabrics, Dyneema® blended denim fabrics, Dyneema® knitted blended fabrics and Dyneema® woven blended fabrics are all new fabrics made by blending Dyneema® fibers with other fibers through different weaving methods. Dyneema® ® fibers to improve the performance of fabrics. Can be collectively referred to as Dyneema® blended fabrics.

The Dyneema® Composite Fabrics (Dyneema® Composite Fabrics, referred to as: DCF) is a film made of the middle layer of Dyneema® fiber and the upper and lower polyester thin laminations. The middle layer is a solid layer of Dyneema® fiber and can be laminated with other films to take its strength and durability to new heights. Improved tear, puncture and abrasion performance while reducing weight and bulk. Dyneema® composite fabric is currently the strongest performance fabric among Dyneema® fabrics.

Dyneema® composite fabric

Predecessor – crude benzene fiber

The predecessor of Dyneema® composite fabric is Cuben Fiber. Although the name is “fiber”, crude benzene fiber is actually a non-woven composite film made of ultra-high molecular weight polyethylene fiber (UHMWPE) and polyester and other films laminated.

Originally developed by Cubic Tech Corporation (Cubic Tech Corporation) to make sails for racing sailboats. In 2009, Cubic Technology Company named the performance-optimized crude benzene fiber as CTF3. In 2015, Cubic Technology Company was acquired by DSM subsidiary Dyneema, and crude benzene fiber (CTF3) was also renamed as Dyneema® composite fabric (abbreviation: DCF) .

Fabric performance

Dyneema® Composite Fabrics (hereinafter referred to as DCF) come in different thicknesses and weights and can be used to manufacture different types of products. The heavier DCF has a higher density of Dyneema fibers which increases its strength. Lamination of DCF hybrid variants with polyester film makes it more wear resistant. In order to make equipment products have better performance, manufacturers will laminate DCF and other fabric films together. DCF and films with different properties are laminated, and the properties of the final fabric will also be different.

Regardless of its ugly appearance, DCF will give full play to the performance of Dyneema® fiber. In addition to UV resistance, it also has three major properties.

No.1

high tensile strength

As mentioned above, the tensile force of Dyneema® fiber in the middle layer of DCF is 15 times that of steel of the same quality, and DCF can reach 10 times that of steel of the same quality. The 2MM diameter Dalima line can easily lift up to 300kg. That’s an amazing indicator!

No.2

ultra light

For equipment made of DCF, using DCF and ordinary fabrics with the same tensile strength, DCF will be 25-50% lighter in weight. Assuming that a piece of ordinary fabric equipment with the same tensile strength costs 1kg, then the weight of the equipment made of DCF will only be 250g~500g, which can easily reduce the outdoor load.

No.3

Highly water repellent

Rain, ice and snow in the outdoors are a deadly threat or burden to the human body. Therefore, the water repellency of the equipment is very critical. The highly water-repellent performance can reduce the weight burden caused by the equipment absorbing water, and at the same time better protect the safety of the human body.

After reading it, do you think DCF is a proper black technology fabric!

At present, there is no domestic manufacturer that can stably mass-produce this kind of fabric. Making it into equipment has very high requirements for production technology and equipment. The sewing process will directly affect the performance of the fabric, and it is also very difficult to control the production capacity and yield. This is one of the reasons why such excellent fabric products have not been widely used in outdoor clothing and equipment except for being expensive.